Challenge

Bio-Rad RSL is a Belgian production and research unit within the Bio-Rad Clinical Diagnostics group. RSL is specialised in producing the HPLC accessories used in diagnostic kits for, amongst other things, diabetes monitoring.

The production of resins and HPLC cartridges is central to this. These cartridges are produced by filtering suspensions under high pressure.

Until recently, these cartridges were inserted, filled and dispensed manually and then automatically pressed into 15 stations served by six operators. Bio-Rad RSL entrusted IMA with the task of fully automating the production process.

The solution

IMA has developed the following solution:

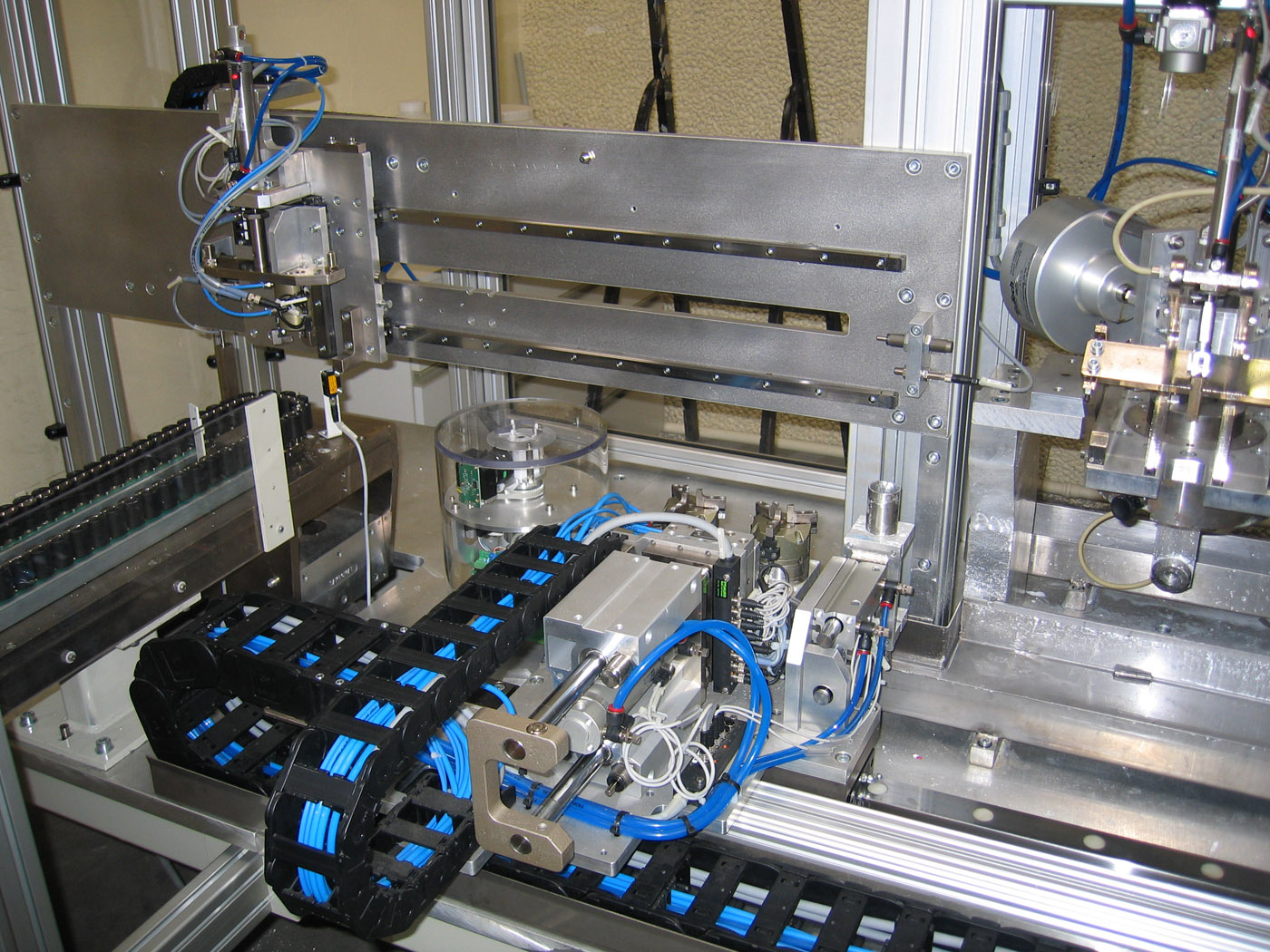

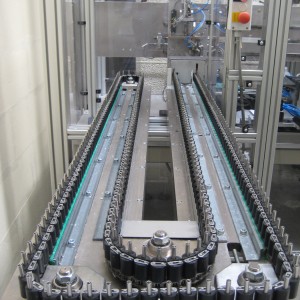

- The empty cartridges are manually placed in a feeder belt, and the full cartridges are removed.

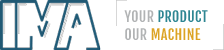

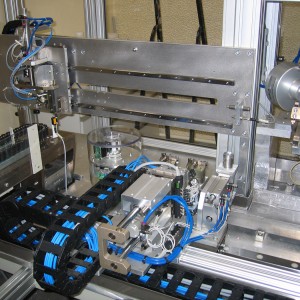

- A manipulator places empty cartridges in one of the seven stations, which fill the cartridges with a dosing pump and then compress the cartridge filling.

- The filled cartridges are then automatically removed from the pumping station and returned to the conveyor belt

Due to the high operating pressure of 400 bar, the pumping station is designed for high pressure and is made of stainless steel. There is also an automatic rinse cycle (with an end-of-day protocol), a start-up module, and an identification scanner.

Savings

Because the automatic filling station achieves the same production volume with one operator as the manual application did with 4 or 5, BIORAD can raise both the productivity of the process and the quality of the products.

Vragen over machinebouw?

Aarzel niet ons te contacteren!

Céline helpt u graag verder!

Questions About machine building?

Don’t hesitate to contact us!

Céline will help you!