Challenge

Daikin Europe NV designs and manufactures a wide range of technologically advanced air conditioning equipment. Every year, 700,000 air conditioners are made in Ostend. Daikin Europe NV employs about 1,400 people there.

The assignment consisted of replacing an old system (the heat exchangers were mostly handled manually) by an automated transport system in which specific machines and processes were integrated. The aims were:

- Increasing production capacity by 30%, such that a heat exchanger can be finished every 35 seconds.

- The option of assembling a new type of heat exchanger in addition to the existing types.

- Eliminating manual operations, which can lead to a productivity increase of up to 15%. This should also reduce the rate of rejection by damage by 90%.

Last but not least, this also represents a significant ergonomic improvement for the operator. In addition, “total mix” production (different types of heat exchangers on the same line) should be possible while maintaining the sequence of products (even after parallel processes).

The solution

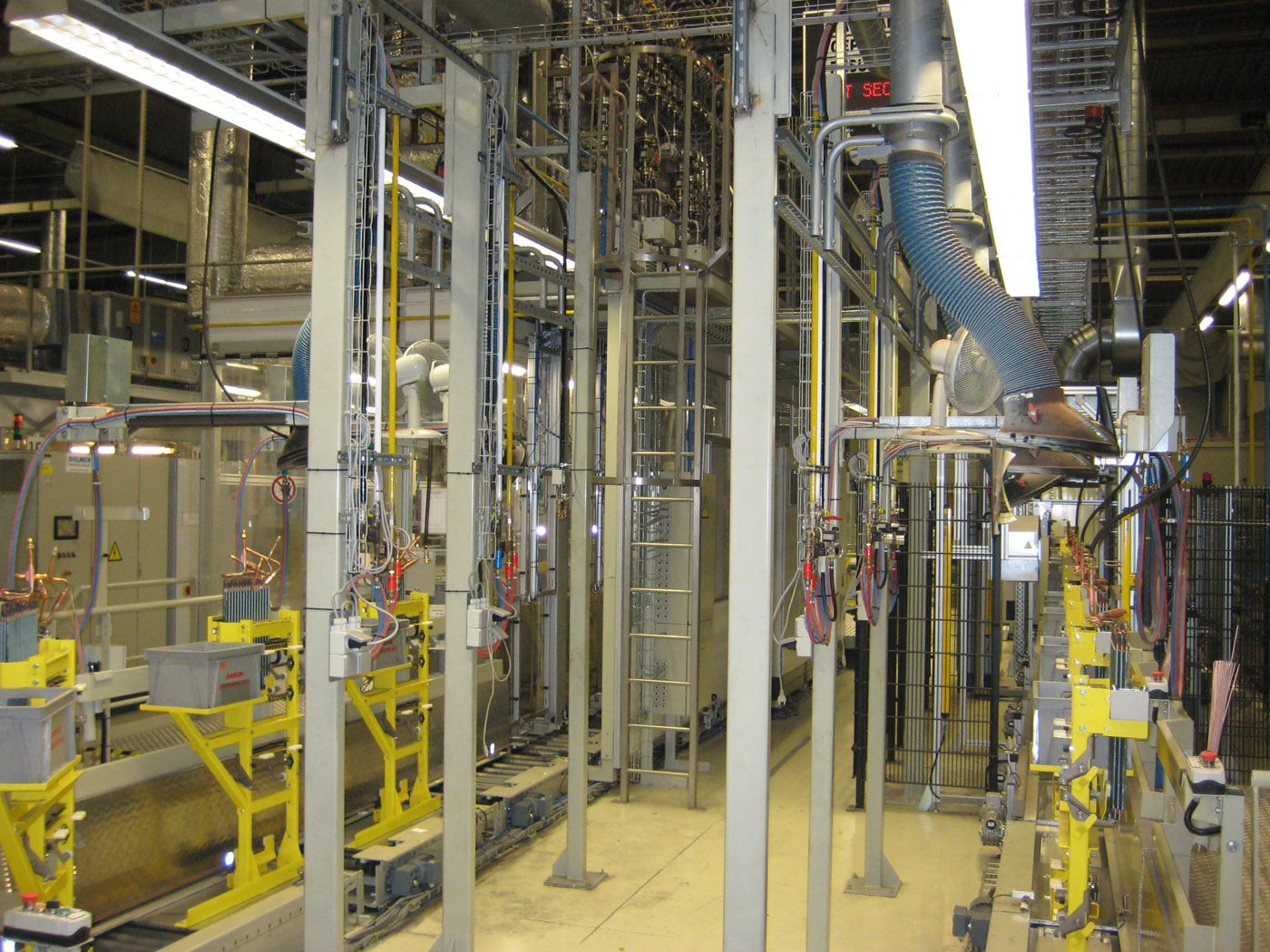

For this, IMA worked out a solution by combining the following technologies:

- A loop transport system connects a number of automatic processes and workstations and in, every case, brings the workpiece carriers to the operator.

- Products of different sizes are put on workpiece carriers whose formats can be automatically adjusted.

- Assembly and brazing operations are performed on the heat exchanger at various ergonomic workstations. • The heat exchangers undergo a pressurisation and leak test. For this, five parallel leak test cabins are provided.

Savings

In addition to increasing the production capacity, this machine permits greater flexibility and a considerable reduction in product damage.

Vragen over machinebouw?

Aarzel niet ons te contacteren!

Céline helpt u graag verder!

Questions About machine building?

Don’t hesitate to contact us!

Céline will help you!