Challenge

When the R&D department of crisp manufacturer Pringles develops new flavours, they are first subjected to consumer research. To this end, samples are produced with different seasonings and combinations. The flavours that are well received are then put into production.

Until now, these samples have mainly been produced manually. This is a labour-intensive process in which the crisps are heated in an ordinary oven, then placed on a belt where a small-scale distribution system seasons them before they are put into boxes manually.

Solution

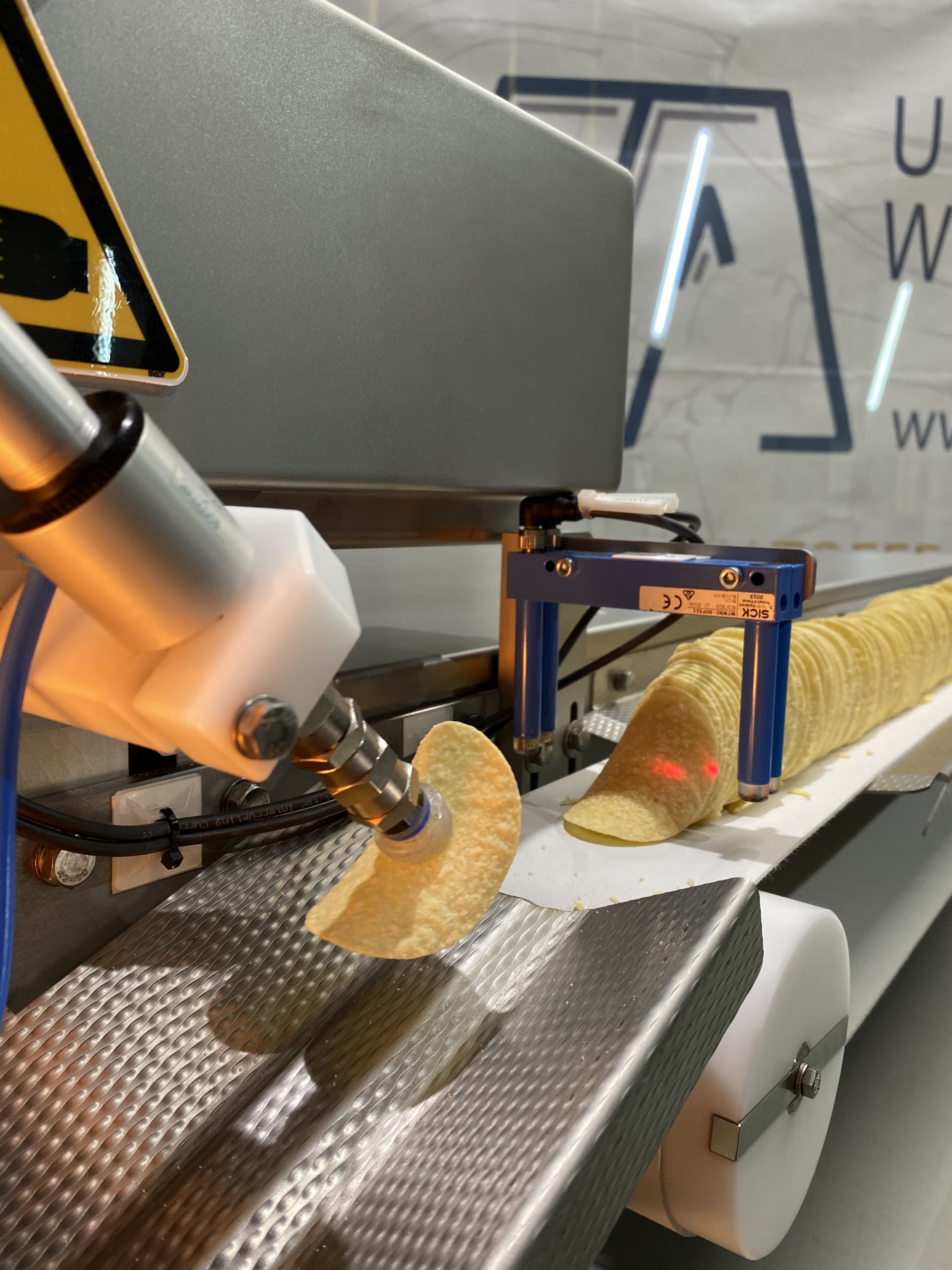

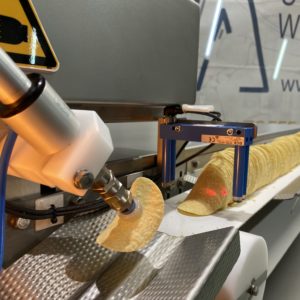

IMA & Verhaert have designed a machine that does all this automatically: the crisps are placed on the belt and seasoned before falling into a box at the end. Faster switching between flavours is possible and the heating technique ensures that the flavours are applied more effectively.

Hygiene is an additional challenge when developing a machine for the food industry. And that means no corners and edges, because everything must be 100% cleanable. Our design is easy to dismantle and most pieces simply fit in the dishwasher.

Since the machine needs to be easily accessible, safety was a further focal point.

Tim Vandeberghe – R&D Kellogg’s – Lead Food Designer:

“A smooth and professional collaboration during this time of coronavirus has ensured that we can now respond much more quickly, accurately and in larger quantities to sample requests required for the development of flavours, consumer research, sales purposes, etc. We are very satisfied with the quality, flexibility and timely delivery of IMA’s work. The IMA team thinks along with us in a solution-oriented way and keeps to all the agreements made.”

Snackmasters!

Did you see the Pringles factory on the Snackmasters programme on VTM? Well, we feel rather like the snackmaster in this project! Watch the video here.

Added value

This installation enables the R&D department to respond more quickly and accurately to sample requests, even for large quantities. Thanks to the heating technique, the seasoning is applied in a more targeted way.

Vragen over machinebouw?

Aarzel niet ons te contacteren!

Céline helpt u graag verder!

Questions About machine building?

Don’t hesitate to contact us!

Céline will help you!